ALEXANDER CUBELLIS

CIV102 Truss Bridge Design

Scoping the Problem:

Given the time constraints our group developed a set of high level objectives that we ordered in rank of importance as follows:

1. Making the bridge as safe as possible

2. Making the design inexpensive

3. Developing an aesthetically pleasing design

In addition, our group developed a list of DFX’s that would allow us to meet the requirements of the stakeholders (as specified in the RFP document).

These DFX’s include:

1. Design for Safety

2. Design for Constructability

3. Design for Effectiveness

4. Design for Aesthetics

The Iterative Process and Quantitative Analysis Methods:

Our group began the decision-making process by looking at reference truss designs. Some of the original designs in contention included the following: However, we immediately discarded the bowstring arch truss design due to our lack of technical experience in calculating the forces in parabolic or arched trusses (as this is outside of the scope of the CIV102 course content). In addition, the camelback and K-truss designs have cross-sectional members that make them statically indeterminate and would have to be calculated using unconventional means. Therefore, our group decided to perform sample calculations on both the Warren and Pratt trusses to determine which of the two would be more cost-effective.

However, we immediately discarded the bowstring arch truss design due to our lack of technical experience in calculating the forces in parabolic or arched trusses (as this is outside of the scope of the CIV102 course content). In addition, the camelback and K-truss designs have cross-sectional members that make them statically indeterminate and would have to be calculated using unconventional means. Therefore, our group decided to perform sample calculations on both the Warren and Pratt trusses to determine which of the two would be more cost-effective.

We decided instead to use a single span Warren truss as this would allow the design to be easily constructible as all of the member lengths would be equivalent. However, as we began to calculate the tensile loads at mid-span, we found that the HSS members required would be extremely large and therefore would be more expensive. Moreover, the reaction force at the support was 428 KN and therefore the minimum HSS value that would safely carry the load in the compressive member would be 178 x 178 x 9.5.

We decided that the only way to reduce the forces in the members would be to reduce the distance over which the load is distributed. To do this, multiple spans would be needed as opposed to a single span. Our group decided that a minimum of three spans would be needed. We reasoned that it would not be possible to use two spans because the bridge would be asymmetrical, and this would not make the structure aesthetically pleasing. Moreover, the mid-span column would have to be situated in the river bed, yet it is stated explicitly in the stakeholder’s manifest that no columns are permitted to be situated in the river bed due to environmental concerns.

We were hesitant to use three spans because this would ultimately increase the cost needed for the footings. However, since the load in the members decreased due to the lower reaction forces, members with a lower cross-sectional area could be chosen to support the load and thus cheaper, thinner members could be used in the design of the truss. Our group then calculated both the cost of using a single span vs. three spans and verified that in fact using three spans was cheaper. (These calculations are outlined in the RFP documentation).

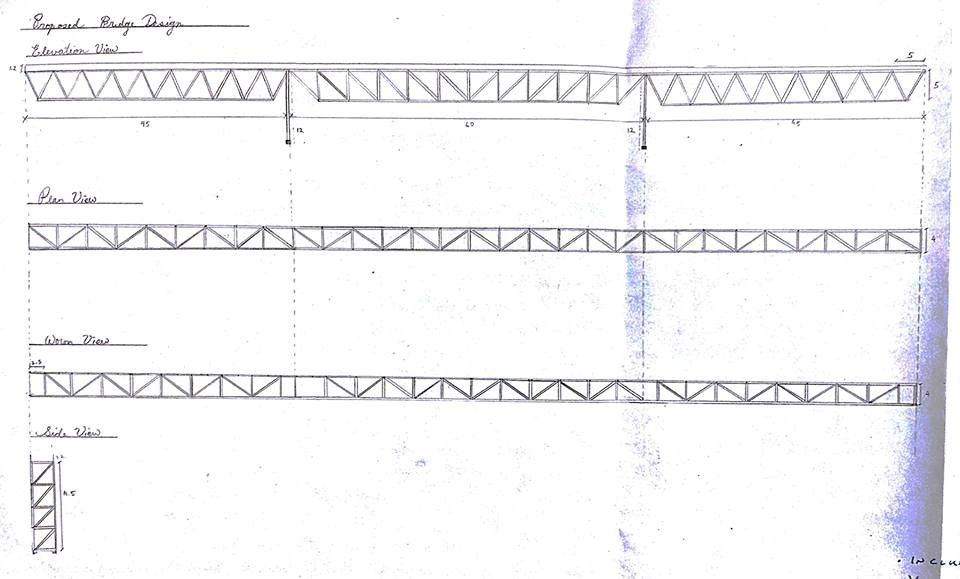

The final decision that our group was required to make involved choosing what combination of Warren and Pratt trusses could be used to minimize the cost. Our group decided to use a 45 Warren—60 Pratt—45 Warren configuration. This configuration allowed for the top, bottom and diagonal members to be integer lengths so as to improve constructability. We chose the 45 metre distance for the Warren trusses so that there would be enough distance between the river bed and the column so that large excavators could easily access the site while not interfering with the river ecosystem.

The Final Solution can be seen in our schematic in the slide show.

Truss Bridge Design: Request for Proposal

This proposal will demonstrate why the pedestrian bridge design as illustrated in the enclosed documentation should be selected by the City of Toronto to span the valley in the Lake Front Trail region. Specific design decisions will be explained to reinforce the validity of the claim that this design is the optimal design for the constraints specified.

Design for safety:

-

Live load and safety factors: To establish that the bridge is safe the live load and the assumed load of the bridge are considered in the design of the members. A safety factor of 3 is used in determining the HSS for the compression members and a safety factor of 2 for the tension members.

-

Deflection: The engineering standard for the acceptable deflection of a bridge is determined by taking the ratio between the deflection and the span of the bridge. This ratio was determined to be less than 1/500 and therefore the deflection is not visible to the naked eye. Therefore the bridge is both structurally sound and appears safe to a pedestrian or cyclist wanting to cross the bridge. I.e. the bridge does not appear to be sagging.

-

Natural Frequency calculations: The natural frequency of this bridge design is 1.5 Hz. This figure is significant as the natural frequency must not equal 2 Hz, since this is the accepted value for the frequency of the footfalls of an individual when they are walking. If the frequencies are close in value or equivalent, there is the potential for the bridge to resonate unsafely when someone (or a group of people) is/are walking across it and the bridge could potentially collapse.

-

Wind-bracing calculations: The wind forces at each joint was determined and through truss analysis appropriate HSS values were assigned to each member to ensure structural stability.

-

Railing: The height of the average man is 1.8 m and therefore by convention a railing is made to be 60% of this value (approximately 1.1m). However, since cyclists will also use this bridge there is the potential for the cyclist to exceed this height while riding their bicycle and therefore a larger height was chosen of 1.2. (Calculations based on the size of a standard bicycle and recommended saddle height for a 1.8 m tall man) (Ebicycles.com).

-

Avoiding the flood line: During a flash flood a river can be subjected to an increase in height up to 10 feet (approximately 3 m) therefore providing ample room below the bridge in the case of a flood scenario.

Design for cost-effectiveness/constructability/environment:

-

Comparative Cost Consideration (Warren vs. Pratt): The cost of the Warren truss was compared to the cost of the Pratt truss for the 45 m and 60 m spans. The most cost-effective combination of the two was chosen: 45 m Warren, 60 m Pratt, 45 m Warren. The cost of the 45 m Warren was $45 761, and $90 716 for the Pratt truss.

-

Number of columns/footings: To minimize the cost the number of footings must be at a minimum. In this case two footings were used (for 3 spans). Although it would have been theoretically possible to use a single span and therefore decrease the cost even more, this compromises safety since the forces in the members are dangerously high and the deflection increases to unsafe values.

-

HSS Designations and member lengths: to minimize the number of unique HSS members that need to be purchased, the span of the bridge was designed to use as many members of equivalent length as possible. In the design of the span all of the members are 5 m, 5.59 m, or 7.07 metres. In addition, to prevent the number of unique HSS members that need to be purchased the same type of HSS designation was used in the Warren diagonal members as in the Pratt diagonal members.

-

Design of mid-span: A mid-span of 60 m was selected to provide ample space for the columns to be constructed. Since the width of a standard 390DL Hydraulic excavator is 4.26 m, this design provides enough space between the columns and the river to ensure that the excavation does not interfere with the river ecosystem (cat.com).

Aesthetics

-

Decision to use a deck truss design: This bridge is designed to carry cyclists and pedestrians across a valley in the Lake Front Trail. This region around Lake Ontario is heavily forested and quite scenic. To preserve the natural beauty of the region, the bridge is designed to have an unobstructed view of the valley from the bridge so that primary stakeholders, the pedestrians and cyclists, may enjoy the scenery around them. A through bridge design as opposed to a deck truss fails to consider this factor.